本文总结了15个在cnc加工中心机床常遇见的机器故障因素和解决对策,机器故障则会影响加工的效率,所以对故障因素的排查显得尤为重要,如何您掌握了以下这几种方法,则在关键时刻起到出乎意料的表现。

本文主要内容:cnc加工中心机床常见故障诊断与对策

一: 手轮故障

原因:

1.手轮轴选择开关接触不良

2.手轮倍率选择开关接触不良

3.手轮脉冲发生盘损坏

4.手轮连接线折断

解决对策:

1.进入系统诊断观察轴选开关对应触点情况 (连接线完好情况),如损坏更换 开关即可解决

2.进入系统诊断观察倍率开关对应触点情况 (连接线完好情况),如损坏更换开关即可解决

3.摘下脉冲盘测量电源是否正常,+与A,+与B 之间阻值是否正常。如损坏 更换

4.进入系统诊断观察各开关对应触点情况,再者测量轴选开关,倍率开关,脉冲盘之间连接线各触点与入进系统端子对应点间是否通断,如折断更换即可

二.X Y Z 轴及主轴箱体故障

原因:

1.Y Z 轴防护罩变形损坏

2.Y Z 轴传动轴承损坏

3.服参数与机械特性不匹配。

4.服电机与丝杆头连接 变形,不同轴心

5.柱内重锤上下导向导轨松动,偏位

6.柱重锤链条与导轮磨损振动

7.轴带轮与电机端带轮不平行

8.主轴皮带损坏,变形

解决对策:

1.防护罩钣金还

2.检测轴主,负定位轴承,判断那端轴承损坏,更换即可

3.调整伺服参数与机械相互匹配。(伺服增益,共振抑制,负载惯量)

4.从新校正连结器位置,或更换连接

5.校正导轨,上黄油润滑

6.检测链条及导轮磨损情况,校正重锤平衡,上黄油润滑

7.校正两带轮间平行度,动平衡仪校正

8.检测皮带变形情况损坏严重更换,清洁皮带,调节皮带松紧度

三. 导轨油泵,切削油泵故障

原因:

1. 导轨油泵油位不足

2. 导轨油泵油压阀损坏

3. 机床油路损坏

4. 导轨油泵泵心过滤网堵塞

5. 客户购买导轨油质量超标

6. 导轨油泵打油时间设置有误

7. 切削油泵过载电箱内断路器跳开

8. 切削油泵接头漏空气

9. 切削油泵单向阀损坏

10. 切削油泵电机线圈短路

11. 切削油泵电机 向相反

解决对策:

1.注入导轨油即可

2.检测油压阀是否压力不足,如损坏更换

3.检测机床各轴油路是否通畅,折断,油排是否有损坏。如损坏更换

4.清洁油泵过滤网

5.更换符合油泵要求合格导轨油

6.从新设置正确打油时间

7.检测导轨油泵是否完好后,从新复位短路

8.寻找漏气处接头,从新连接后即可

9.检测单向阀是否堵塞及损坏,如损坏更换

10.检测电机线圈更换切削油泵电机

11.校正切削油泵电机 向,即可

四.加工故障

原因:

1.X Y Z 轴反向间隙补偿不正确

2.X Y Z 向主镶条松动

3.X Y Z 轴承有损坏

4 机身机械几何精度偏差

5.主轴轴向及径向窜动

6.系统伺服参数及加工参数调整不当

7.客户编程程序有误

8.X

Y Z 轴丝杆,丝母磨损

解决对策:

1.千分表校正正确反向间隙

2.调整各轴主镶条松紧情况,观测系统负载情况调整至最佳状态

3.检测轴承情况,如损坏更换

4.大理石角尺,球杆仪检测各项目几何精度,如偏差校正

5.修复主轴内孔精度,主轴轴承窜动间隙,如不能修复更换

6.调整伺服位置环 ,速度环增益,负载惯量比,加工精度系数,加减速时间常数

7.优化,调整编程工艺

8.借助激光干涉仪进行丝杆间隙补偿

五.松刀故障:

原因:

1.松刀电磁阀损坏

2.主轴打刀缸损坏

3.主轴弹簧片损坏

4.主轴拉爪损坏

5.客户气源不足

6.松刀按钮接触不良

7.线路折断

8.打刀缸油杯缺油

9.客户刀柄拉丁不符合要求规格

解决对策:

1.检测电磁阀动作情况,如损坏更换

2.检测打刀缸动作情况,损坏更换

3.检测弹簧片损坏程度,更换弹簧片

4.检测主轴拉爪是否完好,损坏或磨损更换

5.检测按钮损坏程度,损坏更换

6.检测线路是否折断

7.给打刀缸油杯注油

8.安装符合标准拉丁

六、机床不能回零点

原因:

1.原点开关触头被卡死不能动作

2.原点挡块不能压住原点开关到开关动作位置

3.原点开关进水导致开关触点生 接触不好

4.原点开关线路断开或输入信号源故障

5.PLC 输入点烧坏

对策:

1.清理被卡住部位,使其活动部位动作顺畅,或者更换行程开关,想学习UG编程可以加QQ群304214709领取UG学习资料和课程。

2.调整行程开关的安装位置,使零点开关触点能被挡块顺利压到开关动作位置

3.更换行程开关并做好防水措施

4.检查开关线路有无断路短路,有无信号源(+24V 直流电源)

5.更换I/O 板上的输入点,做好参数设置,并修改PLC 程式

七、机床正负硬限位报警

正常情况下不会出现此报警,在未回零前操作机床可能会出现,因没回零前系统没有固定机械坐标系而是随意定位,且软限位无效,故操作机床前必须先回零点

原因:

1.行程开关触头被压住,卡住(过行程)

2.行程开关损坏

3.行程开关线路出现断路,短路和无信号源

4.限位挡块不能压住开关触点到动作位置

5.PLC 输入点烧坏

对策:

1.手动或手轮摇离安全位置,或清理开关触头

2.更换行程开关

3.检查行程开关线路有无短路,短路有则重新处理。检查信号源(+24V 直流电源)

4.调整行程开关安装位置,使之能被正常压上开关触头至动作位置

5.更换I/O 板上的输入点并做好参数设置,修改PLC 程式

八、松刀故障

原因:

1.气压不足

2.松刀按钮接触不良或线路断路

3.松刀按钮PLC 输入地址点烧坏或者无信号源(+24V)

4.松刀继电 不动作

5.松刀电磁阀损坏

6.打刀量不足

7.打刀缸油杯缺油

8.打刀缸故障

对策:

1.检查气压待气压达到6 公斤正负1 公斤即可

2.更换开关或检查线路

3.更换I/O 板上PLC 输入口或检查PLC 输入信号源,修改PLC

程式

4.检查PLC 输出信号有/无,PLC 输出口有无烧坏,修改PLC 程式

5.电磁阀线圈烧坏更换之,电磁阀阀体漏气、活塞不动作,则更换阀体

6.调整打刀量至松刀顺畅

7.添加打刀缸油杯中的液压油

8.打刀缸内部螺丝松动、漏气,则要将螺丝重新拧紧,更换缸体中的密封圈,

若无法修复则更换打刀缸

九、三轴运转时声音异常

原因:

1.轴承有故障

2.丝杆母线与导轨不平衡

3.耐磨片严重磨损导致导轨严重划伤

4.伺服电机增益不相配

对策:

1.更换轴承

2.校正丝杆母线

3.重新贴耐磨片,导轨划伤太严重时要重新处理

4.调整伺服增益参数使之能与机械相配

十、润滑故障

原因:

1.润滑泵油箱缺油

2.润滑泵打油时间太短

3.润滑泵卸压机构卸压太快

4.油管油路有漏油

5.油路中单向阀不动作

6.油泵电机损坏

7.润滑泵控制电路板损坏

对策:

1.添加润滑油到上限线位置

2.调整打油时间为32 分钟打油16 秒

3.若能调整可调节卸压速度,无法调节则要更换之

4.检查油管油路接口并处理好

5.更换单向阀

6.更换润滑泵

7.更换控制电路板

8.若在紧急情况则在I/F 诊断中强制M64S 为 1A,E60 为 32 后机床暂时能工作

十 、程式不能传输,出现P460、P461、P462 报警

对策:

1.检查传输线有无断路、虚焊,插头有无插好

2.电脑传输软件侧参数应与机床侧一致

3.更换电脑试传输

4.接地是否稳定

十二、刀库问题

原因:

1.换刀过程中突然停止,不能继续换刀

2.斗笠式刀库不能出来

3.换刀过程中不能松刀

4.刀盘不能旋

5.刀盘突然反向旋 时差半个刀位

6.换刀时,出现松刀、紧刀错误报警

7.换过程中还刀时,主轴侧声音很响

8.换完后,主轴不能装刀(松刀异常)

对策:

1.气压是否足够(6 公斤)

2.检查刀库后退信号有无到位,刀库进出电磁阀线路及PLC 有无输出

3.打刀量调整,打刀缸体中是否积水

4.刀盘出来后旋 时,刀库电机电源线有无断路,接触 、继电器有无损坏等现象

5.刀库电机刹车机构松动无法正常刹车

6.检查气压,气缸有无完全动作(是否有积水),松刀到位开关是否被压到位,但不能压得太多(以刚好有信号输入为 则)

7.调整打刀量;

8.修改换刀程序(宏程序O9999)

十三、机床不能上电

原因:

1.电源总开关三相接触不良或开关损坏

2.操作面板不能上电

对策:

1.更换电源总开关

2.检查

A.开关电源有无电压输出(+24V)

B.系统上电开关接触不好,断电开关断路

C.系统上电继电 接触不好,不能自锁

D.线路断路

E.驱动上电交流接触 ,系统上电继电器有故障

F.断路器有无跳闸 G.系统是否工作正常完成准备或Z 轴驱动器有无损坏无自动上电信号输出

十四、冷却水泵故障

1.检查水泵有无烧坏

2.电源相序有无接反

3.交流接触 、继电器有无烧坏

4.面板按钮开关有无输入信号

十五、吹气故障

1.检查电磁阀有无动作

2.检查吹气继电器有无动作

3.面板按钮和PLC 输出接口有无信号

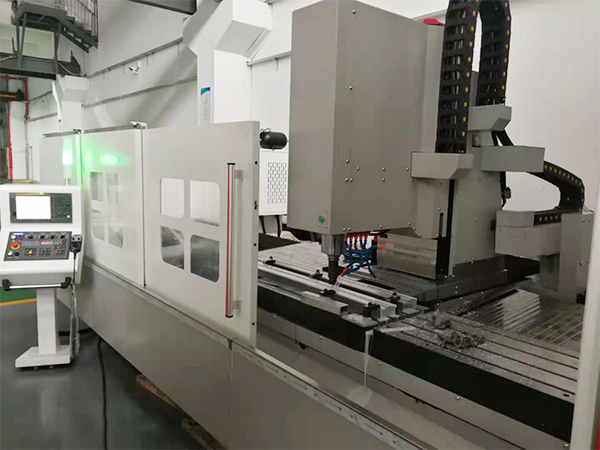

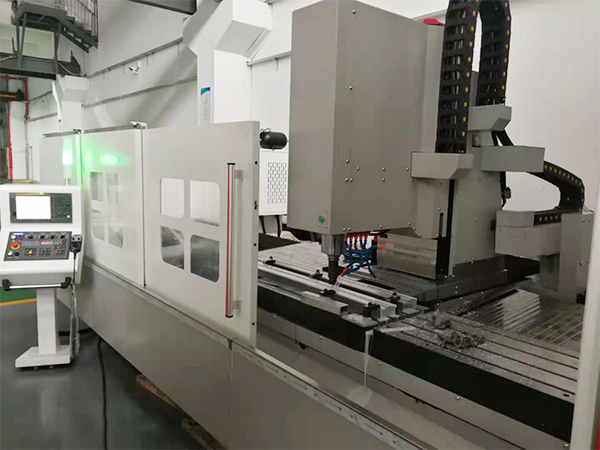

科鼎鑫是一家集产品研发、生产制造、市场销售为一体的民营企业,拥有12年数控设备制造经验,三大生产基地,提供24小时上门服务,可定制cnc加工中心机床,欢迎新老客户咨询服务热线:0510-87553118。